conclusion experiment vickers hardness test|brinell hardness test pdf : Brand manufacturer Perform analysis from Vickers hardness testing data. Hardness is a characteristic . Ask a question. On your computer, open Google. Search for a place. Under the information card for the place on the right side, click " Ask a question " next to the "Questions &.

{plog:ftitle_list}

WEBPara tornar sua experiência como paciente da AACD ainda melhor, agora você poderá acessar aos resultados dos seus exames realizados no Centro de Diagnóstico por Imagem (CDI) aqui no nosso site, de maneira simples, rápida e segura! Clique aqui para consultar seus resultados. Ficou com algum dúvida? Ligue para: (11) 5576-0803.

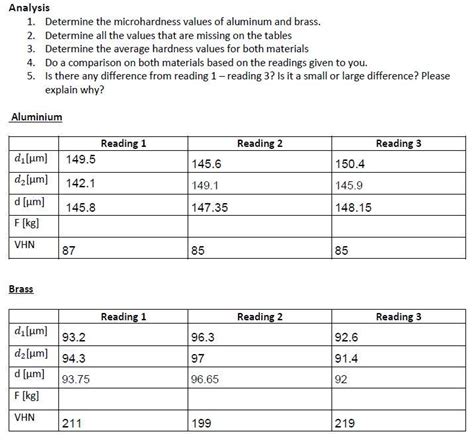

Experiment objective: Vickers hardness tests are used to gauge a material's hardness, and that is its main goal. For quality assurance, choosing materials, and engineering design, this information is essential. A material's strength, resistance to wear, and durability can be .Conclusion: The purpose of this experiment was to determine which of the five .

Perform analysis from Vickers hardness testing data. Hardness is a characteristic .

(I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.Conclusion: The purpose of this experiment was to determine which of the five materials tested was most suitable for the production of 500 HV30 automobile gears. After careful experimentation, calculations and analyzing it was .

CONCLUSION In this experiment, the hardness of the specimen is determined by using a Vickers hardness tester. For each reading, the hardness values gained are slightly different, which are 152.3HV, 161.1HV and 157.4HV respectively. .Perform analysis from Vickers hardness testing data. Hardness is a characteristic of a material not a physical property. Hardness is defined as resistance to indentation and determined by measuring the depth of the .

vickers hardness lab report

Three-dimensional finite element-based numerical analysis of Vickers indenter hardness test was conducted to investigate the effect of frictional conditions and material anisotropy on.

Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force. The advantages of the Vickers hardness test are that .VICKERS HARDNESS TEST: hardness test uses a square base diamond pyramid as the indenter. The. included angle between the opposite faces of the pyramid is l36°. The Vickers .

The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH).

vickers hardness test Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium.

vicker's hardness test

Conclusion. The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The Vickers hardness test allows engineers to inspect materials before they undergo production or post-production processes such as heat .

Hardness of the samples has been evaluated by using Vickers Hardness Test. The Corrosion behaviour of as-received and thermally oxidised samples have been evaluated by using weight loss method.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

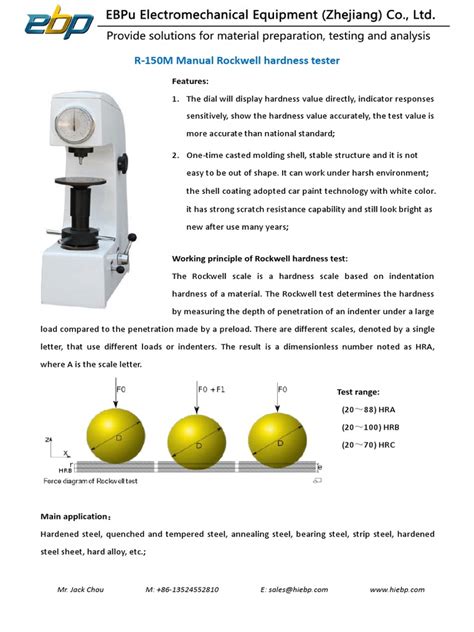

Here are a few of the most important factors to consider to ensure an accurate conclusion from a hardness test. External factors such as light, dirt, vibrations, temperature, and humidity should be controlled . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test .Conclusion: The hardness test experiment was done using a Brinell and a Rockwell Testers. The data obtained was recorded and compared. The experimental and referenced values for each metal were compared. Table 2 showed that the percent differences for Rockwell Test were smaller than for the Brinell test. This concludes that the Rockwell test is .

The Brinell test for this experiment uses steel ball with different diameters which is pressed into a specimen by a different load that is maintained for 15 to 30 seconds. . The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 .Experiment No. 02 ROCKWELL HARDNESS TEST OF A GIVEN SAMPLE Introduction: Hardness of a material is generally defined as resistance to the permanent deformation such as indentation, wear, abrasion and scratch under static and dynamic load. . Conclusion: For hard materials, diamond cone indenter with C scale (black graduation) is used applying .

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).Objective: The Vickers hardness test mainly serves to measure the hardness of materials, its physical durability. Hardness is defined as a material's “resistance to deformation” (#1) and it can vary depending on the material. . Conclusion: The purpose of this experiment was to determine which of the five materials tested was most suitable . Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s experience. In .3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

rockwell hardness test pdf

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. . The main objective of this experiment is to determine the hardness strength of a material by Vickers testing methods. . George E. Sandland who studied at Vickers Ltd. developed an alternative to Brinell hardness in 1921 which was named as Vickers hardness. In the Vickers test, the entire calculation is independent of the size of the indenter .

15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: It is similar in principle to Rockwell hardness test, but utilizes a different indentor and different magnitudes of loads. The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard .Brinell test in Sweden in 1900. The oldes t of the hardness test methods in common use today, the Brinell test is frequently used to determine the hardness of forgings and castings that have a grain structure too course for Rockwell or Vickers testing (http ://www.instron.co.uk ). 2.2. Case hardening improves both the wear

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . In conclusion, the Vickers hardness testing method is a powerful technique for assessing the hardness of various materials. Its principles are grounded in precise indentation measurements, allowing for accurate material characterization and evaluation. With its wide range of applications in material science, manufacturing, and research, the .Meyer Hardness P πd = VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.

rockwell and brinell hardness test ppt

Vickers hardness testing also is known as the Diamond pyramid hardness test. Because we use the Diamond pyramid as the indenter. The same testing machine which is used for the Brinell hardness testing machine can be used for the Vicker’s hardness test also.; Unlike Brinell hardness testing, we do not need to change the indenter for the different materials. we . 1 Abstract: The task designate for this experiment was to find a material that satisfied the requirements of a Vickers Hardness value of at least 500 HV30 for a automobile manufacturer to produce gears. Five different sample materials were provided for testing: 6061-T6 Aluminum, 1018 Cold Rolled Steel, 360 Half Hard Brass Alloy, 110 Copper, and Zirconia .

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.See 5.10 for the proper reporting of the hardness level from measurements of area or depth of the indentation made by and scale. forcing a specified indenter into the surface of a material under as-found condition, n— specified static loading conditions. 3.2.5 the state of the hardness ma- chine as reflected by the initial verification .

The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness test follows the brinell principle, in that an indenter of definite shape is pressed into the material to be tested, then the load is removed and .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

rockwell and brinell hardness testing machine

Descubra curiosidades, bastidores, novidades, e até segredo.

conclusion experiment vickers hardness test|brinell hardness test pdf